- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

Polymer Extrusion Machine Co -Kneader Single Screw Reciprocating Extruder Cascade Type for PVC and Foaming Compounds

Basic Info

| Model NO. | SJW-100 |

| Warranty | 1 Year |

| Raw Material | Mixing |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Electromagnetic Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008, QS |

| Condition | New |

| Capacity | 300-600 Kg/H |

| Applications | All Kinds of Polymer Mixing |

| Electric Brands | Siemens / Schneider |

| Control | PLC + Touch Screen |

| Extruder Weight | 10000kg |

| Transport Package | Pallet and Wooden Box |

| Trademark | XINDA |

| Origin | China |

| HS Code | 84772010 |

| Production Capacity | 200sets/Year |

Product Description

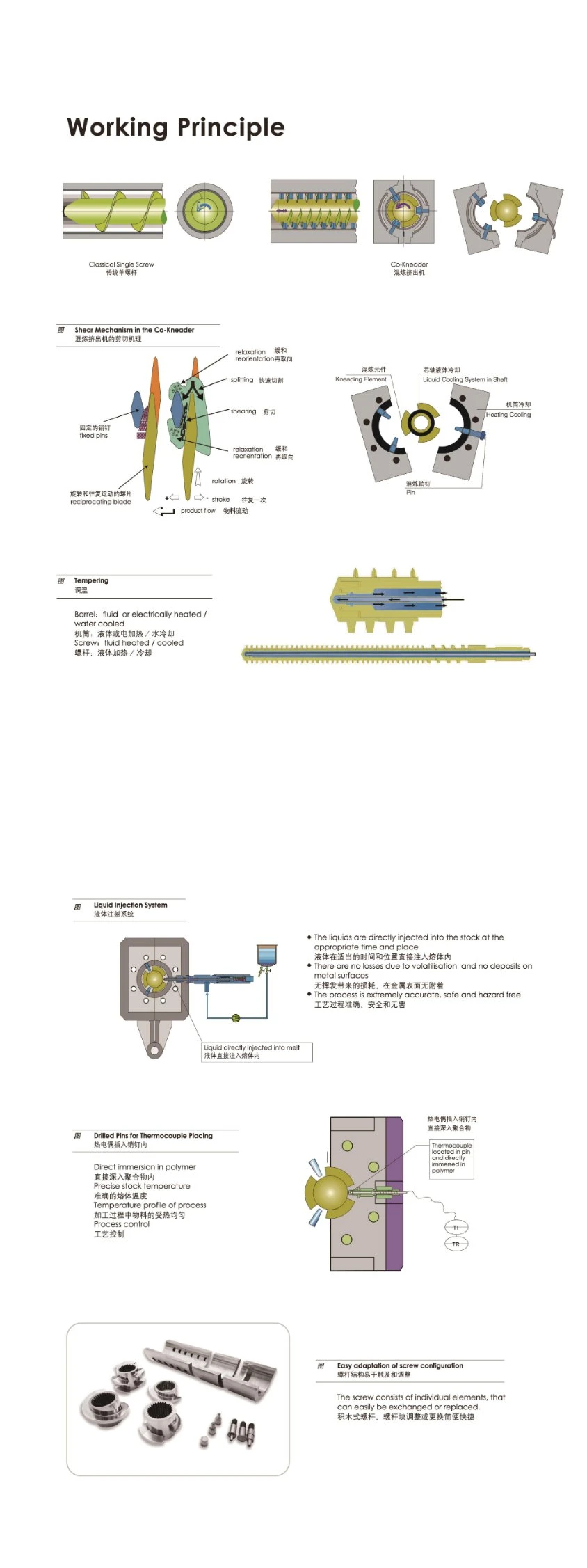

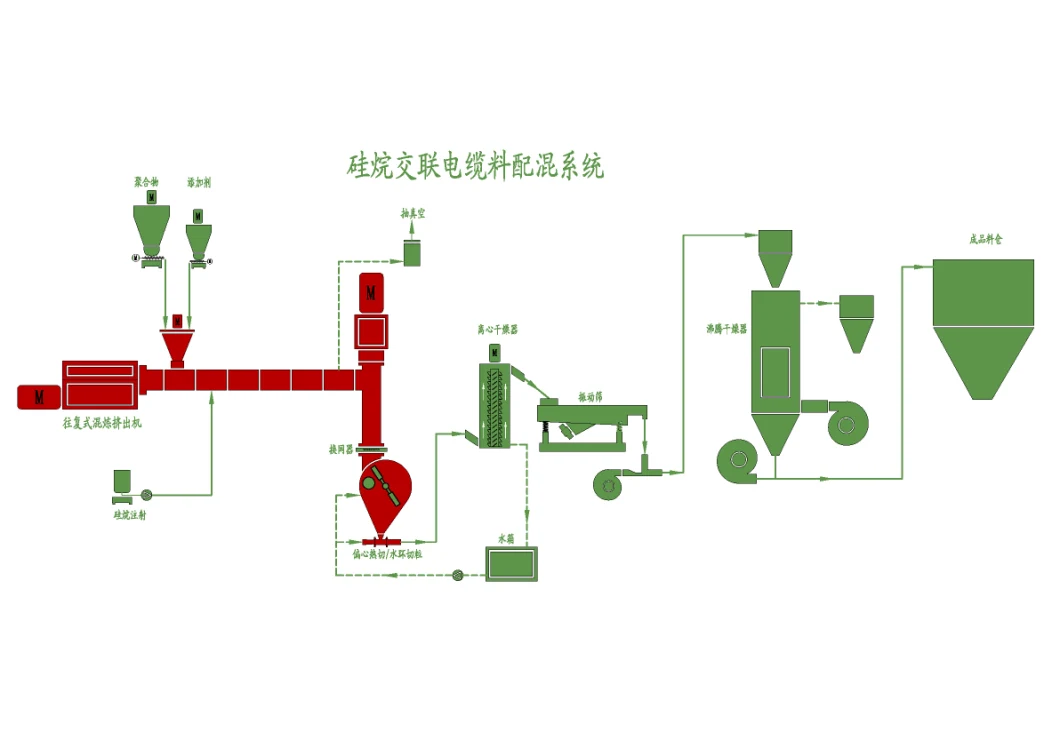

On XINDA Co-kneader, customer can realize:1, the grafting process needs a precise tempeature control, while co-kneader can detect polymer tempeature2, a liquid silane can be injected to melted polymer from the hollow pins 3, good distribution and dispersion can be realized

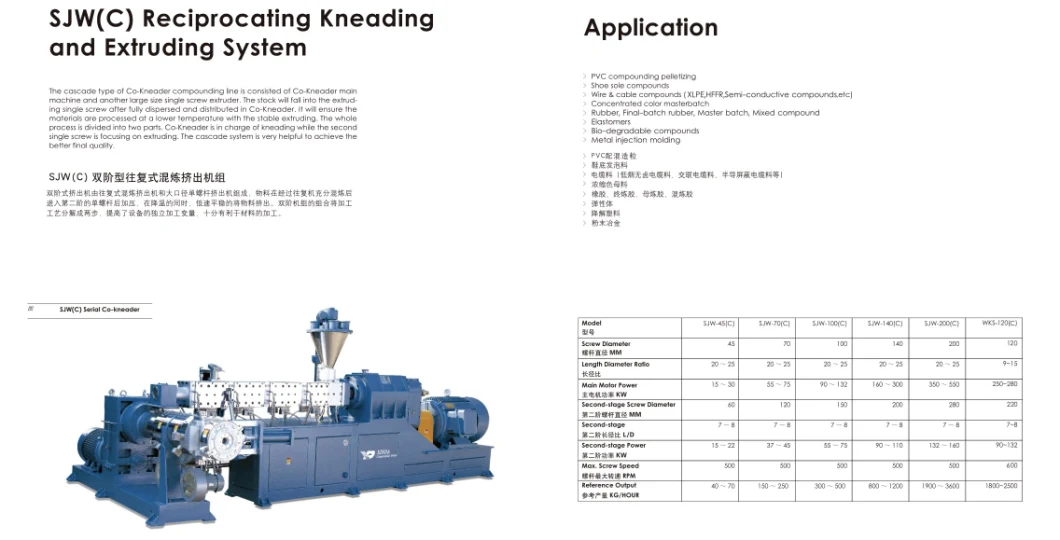

SJW XINDA Type Cascade Three Flights Co-Kneader Compound Extruder for PVC and foaming compounds

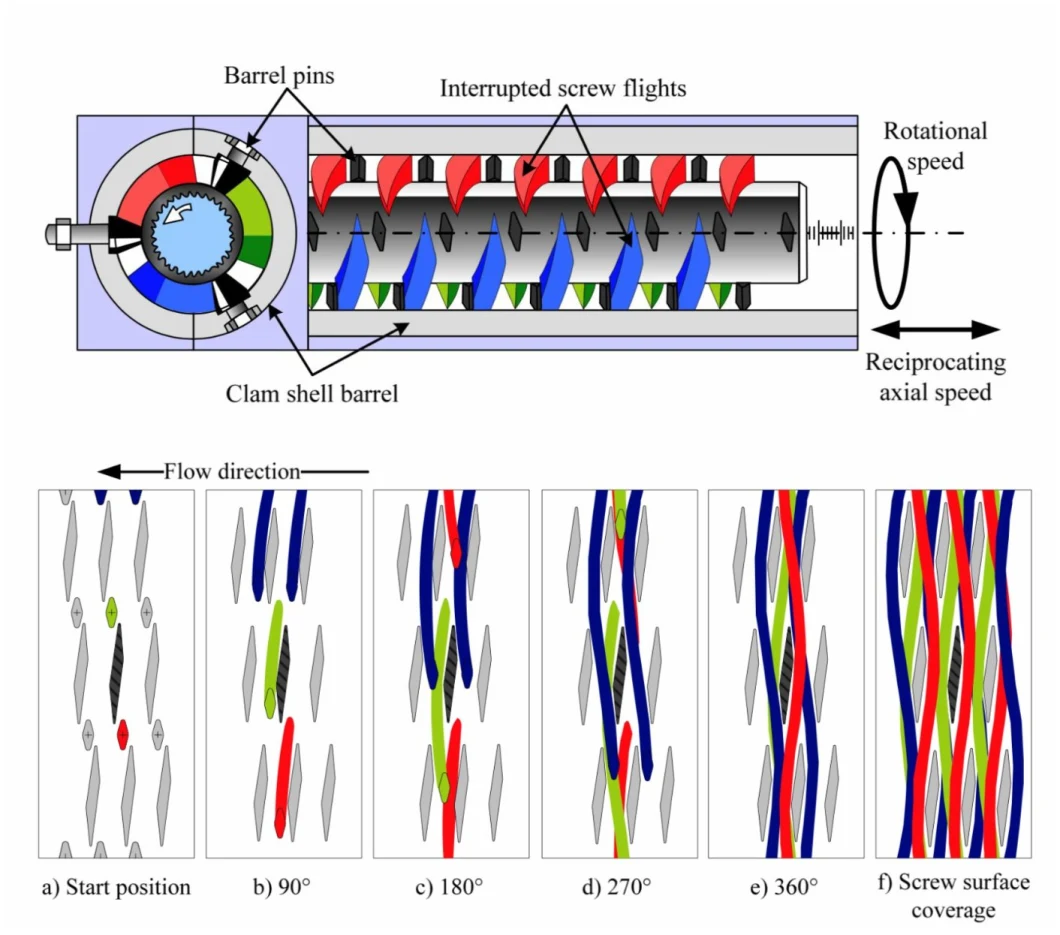

The XINDA SJW Three flights compouding system,each spiral is broken by 3 gaps per revolution to locate the kneading flights, 3 rows of kneading pins,which are individually inserted in the barrel per 120 degree. The reciprocating wobble-box synchronizes the shaft rotation and oscillation so that each revolution of the screw is accompanied by one full stroke forward and backwards.This ensures optimal distributive and dispersive mixing with minimal energy consumption.

Advantages of the XINDA Co-kneaderThe Co-Kneader, a mild-shear rotating and reciprocating single-screw extruder, is designed for shear and temperature sensitive compounds. The flights on the screw are interrupted and interqct with three rows of stationarv kneadina pins located in the barrel wall. The interaction between the moving flights and the stationary pins provide dispersive and distributive mixing simultaneously. Axially opened split barrel guarantees ease of cleaning. Those splined, segmented screw elements and pins can be changed easily according to different processing techniques. In addition, some pins are hollow inside, thermocouples can be inserted to get the accu- rate temperature of the materials inside the barrels, so as to liquid additives injection. Different from other extruders, the kneading process is achieved radially and axially at the same time. All in all, Co-Kneader has outstanding kneading, mixing efficiency and high degree of self-wiping. It is the most suitable for compounding purposes.

Silane cross-linked XLPE Compounds:

Details Images