- Stranding Machine

- Double Twist Machine

- Single Twist Cabling Machine

- Core Wire Extruder Machine

- Sheath Cable Extruder Machine

- Wire Drawing Machine

- Twist Buncher Machine

- Double Twist Stranding Machine

- Foaming Extruder Machine

- Armoring Machine

- Copper Tape Shielding Machine

- Steel Tape Armoring Machine

- Take Up Machine

- Pay Off Machine

- Motorized Pay Off Machine

- Passive Pay Off Machine

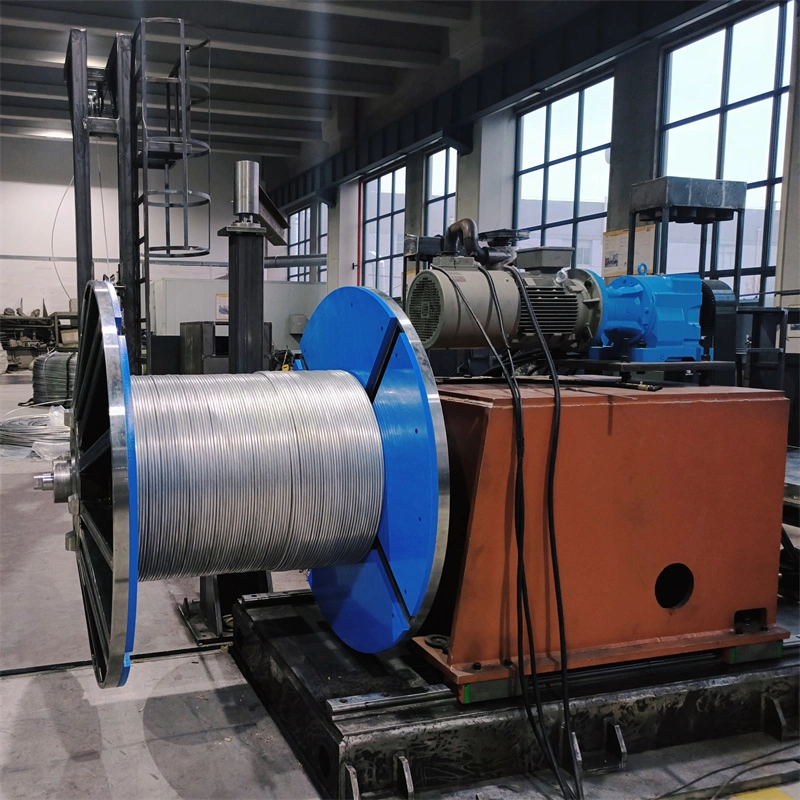

Automatic Rewinding Machine Pay-off Take-up Cable Aluminum Wire Rod Winding Coiling Machine

Basic Info

| Model NO. | OFR1400 |

| Certification | CCC, PSE, FDA, RoHS, ISO, CE |

| Warranty | 12 Months |

| Automatic Grade | Automatic |

| Mould Life | 300,000-1,000,000 Shots |

| Type | High-speed Stranding Machine |

| Usage | Rewinding |

| Material 1 | Rod Rewinding Machine |

| Usage 1 | Rewinding Machine |

| Material 2 | Aluminium Rod Rewinding Machine |

| Warranty of Core Component | 1 Year |

| Transport Package | PE Film |

| Specification | ISO standard |

| Trademark | OPTIMA |

| Origin | China |

| HS Code | 8479400000 |

| Production Capacity | 10 Sets Per Month |

Packaging & Delivery

Package size per unit product 2000.00cm * 3000.00cm * 2000.00cm Gross weight per unit product 3000.000kgProduct Description

1.Application

The equipment is used for rewinding aluminum rods with a diameter of 9.5mm and 12mm. Winding,laying-out,package turning and other actions are intelligently controlled by PLC. The laying-out is driven by overall movement of the servo take-up machine, ensure the aluminum rods after the coiling are arranged orderly, reduce the volume so that easy to transport and store.

2.Equipment list

2.1 Paying-off supporter: 1set

2.2 Horizontal straightening machine: 1 set

2.3 Vertical straightening machine: 1 set

2.4 Taking-up: 1set

2.5 Package turning: 1set

2.6 Electrical cabinet: 1set

| NO. | Description | Data |

| 1 | Expansion and contraction core (outer diameter * inner diameter * width): | Φ 1400*560*900mm |

| 2 | Take-up speed | 200m/min |

| 3 | Take-up diameter | 9.5mm, 12mm |

| 4 | Bearing weight | 3000kg |

| 5 | Max. Dia. of expansion and contraction | Φ560mm |

| 6 | Min. Dia. of expansion and contraction | Φ530mm |

| 7 | Take-up power | 15kW Frequency Motor |

| 8 | Laying-out power | 2kw Servo Motor |

| 9 | Hydraulic station power | 2.2kw |

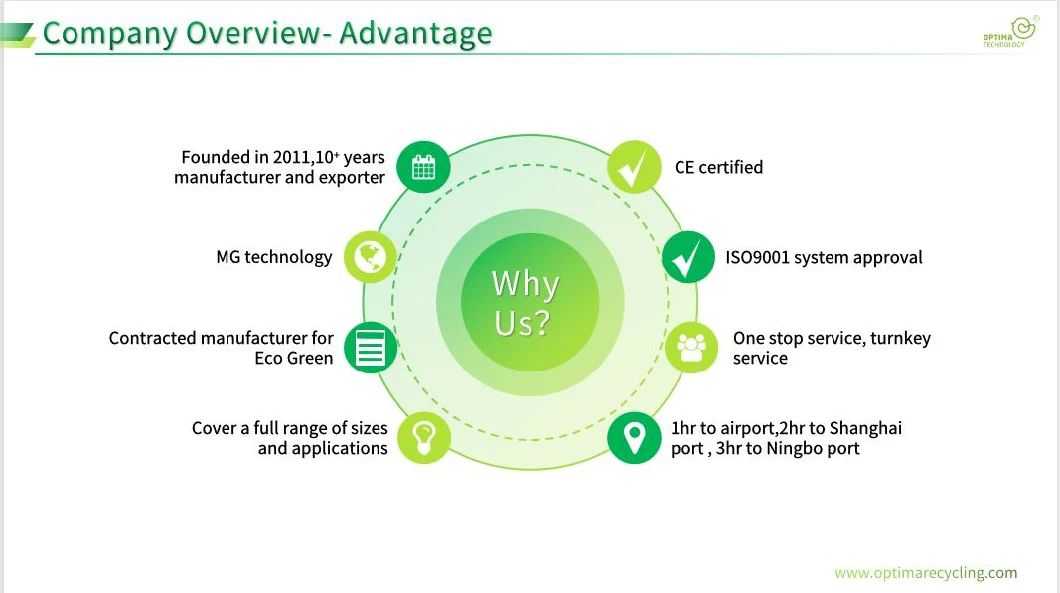

As the guardian of green life, Optima has been adhering to the tenet of "pursuing green fashion and embracing green life" since its establishment, and has focused on the development, production and sales of recycling equipments for more than 10 years.Products include scrap cable recycling machines, waste tire recycling plants, radiator recycling production lines, circuit board processing production lines, hazardous waste crushing systems, shredders, crushers and other related auxiliary equipments.Optima continues to develop green environmental protection technology, unswervingly follows the path of sustainable development, and strives to grow into a top one-stop integrated service provider in the resource recycling industry.In 2019, Dura-shred Recycling Technologies, a well-known enterprise in the tire recycling industry, was introduced to join forces to unite and work together to serve global customers.Optima always adhere to the business philosophy of honesty and win-win cooperation, work hard to create a green and clean-living home.

Our Advantages

Give customers the necessary support. Help them install, maintain or operate a particular equipment. Our service include:1. Send engineers to overseas;2. Online support;3. Overseas maintainance partner;4. Free training.

Q1: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.Q2: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: It is advised to show us the other scrap materials first,our team will evaluate and tell you if it is feasible.

Q3: Will you send the engineer to guide installation?

A: Yes, according to the customer's requirement, engineers will be sent to guide installation,commisioning and training.Q4: Does crusher unit cooling be required?

A: We adopt EU technology for crusher, it doesn't require water cooling unit.Q5: Can we feed armoured cable?

A: The pre-shredder is advised before crusher,so that iron/steel can be removed before materials go through the crusher.

A: Russia,France,New Zealand,Thailand,India,Mexico,Chile,Algeria,etc.

Q7: What is the purity rate of the Cable Wire Recycling Machine?

A: Our Machine is new design and the purity rate can be higher than 99 %.Q8:Is this copper wire recycling machine easy to operate?

A: Yes.Our machine is highly automatic.Machine equipped with PLC system only need one operator to operate the machine.Q9: How long we need to change the blades ?

A: It depends on many factors,the blades installed in granulator can be sharpened,our customers replace blades in 6months to 12 months.Q10: How can I become a distributor?

A: Different country,different agreement. We need to know more a bit about your company capability.